Vi er glade for å kunngjøre at artikkelen vår som er kalt “En høyoppløselig dynamisk probabilistisk materialflytanalyse av syv plastpolymerer; En casestudie fra Norge” (engelsk: “A high-resolution dynamic probabilistic material flow analysis of seven plastic polymers; A case study of Norway”) ble publisert i tidsskriftet Environment International.

Vi ga et rammeverk for å etablere en fortegnelse av polymertyper for hver industrisektor for å implementere sirkulære strategier for å holde plast i lukkede kretser, begrense produksjonen, redusere forbruket og forhindre avfallsgenerering.

Etterpå finnes et kort sammendrag på engelsk og alle som er interessert i å lese hele artikkelen kan laste den ned nedenfor eller på tidsskriftets nettside.

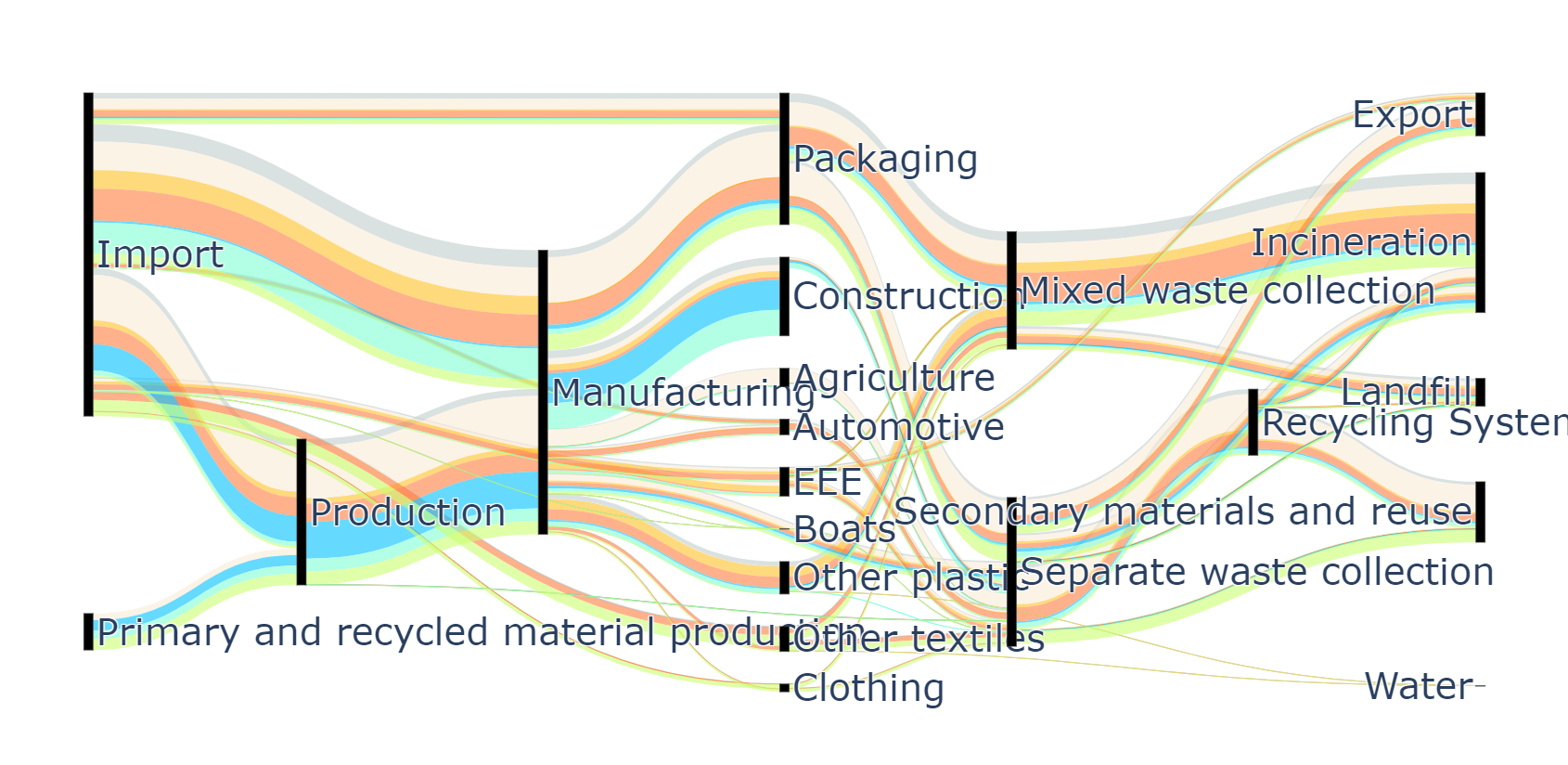

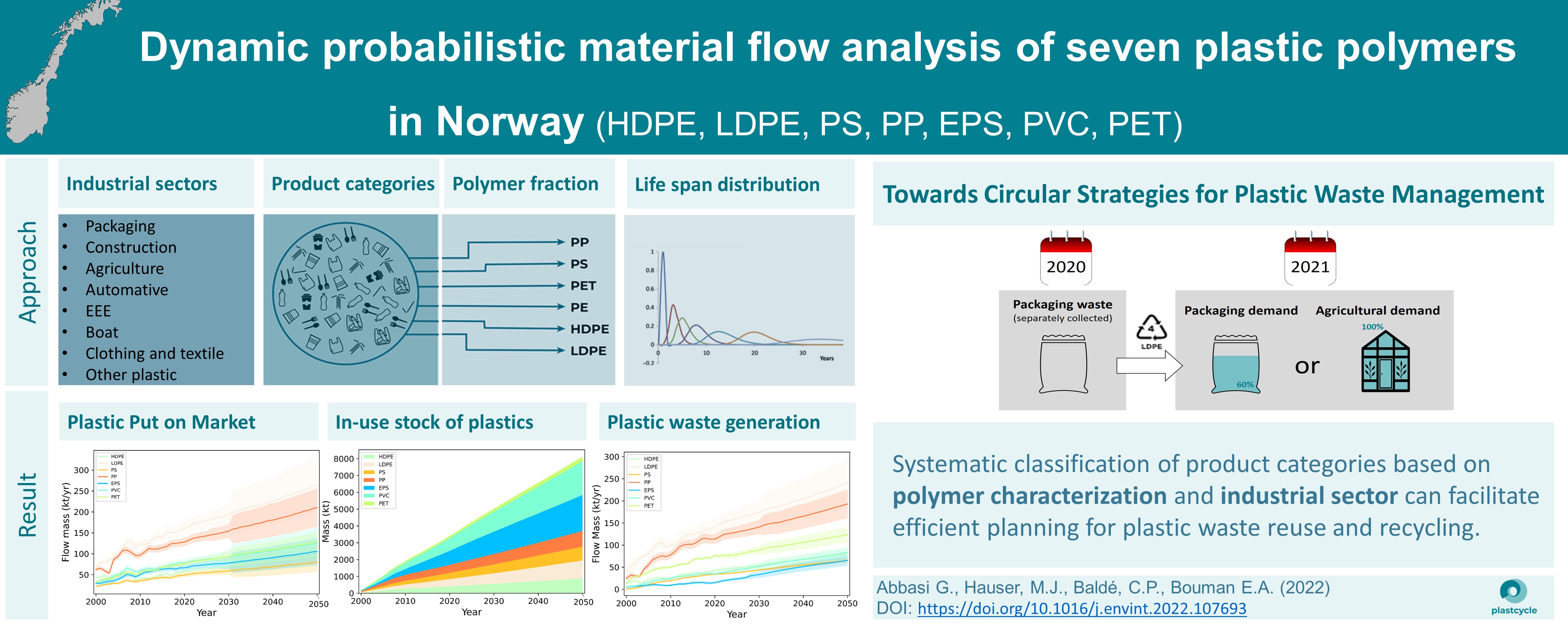

The paper investigates the flows of seven plastic polymers through the whole life-cycle from production and manufacturing, through the use phase to the waste treatment. Seven polymer types (high-density polyethylene (HDPE), low-density polyethylene (LDPE), polystyrene (PS), polypropylene (PP), expanded polystyrene (EPS), polyvinyl chloride (PVC), and polyethylene terephthalate (PET)) were considered. We included nine different industrial sectors, namely packaging, construction, agriculture, automotive, electrical and electronic equipment (EEE), boats, other plastic, clothing, and other textiles with up to 13 individual product categories included per industrial sector. A lifetime was associated to each individual product category, meaning how many years the product category is used after purchase before it is being discarded. The model uses historical data for the years 2000 to 2020 and then presents a business-as-usual scenario until 2050.

We estimated that total of 620 kilotonnes (kt) of plastic was put on the Norwegian market in 2020, which corresponds to 114 kg of plastic per capita. Packaging is the largest contributor of plastic put on the market, followed by construction and other plastic. A total of 3400 kt of plastic (630 kg/capita) are currently in use, the large majority in the construction sectors as pipes, linings or coverings. Waste generation was estimated to be 460 kt corresponding to 83 kg/capita. More than half of this waste comes from the packaging sector. Overall, half of the plastic waste is separately collected and has the potential to be recycled, the other half ends up in the mixed waste stream. Of the separately collected waste, only half (23% of total waste generation) is eventually recycled in Norway. Another ~30% (or 16% of the total waste generation) is exported, mainly for recycling abroad.

Using the separately collected waste in 2020, we developed several inter- or intrasectorial reuse scenarios. For example, 40% of plastic packaging put on the market is in the form of LDPE and currently 60% of it is separately collected. If all the separately collected LDPE waste could be reused as a secondary material for new products, it would supply 60% of LDPE packaging demand in 2021. Alternatively, it could also be used to satisfy the complete demand of LDPE in the agricultural sector. The reuse scenarios show that plastic waste management should be designed specifically for each industrial sector and not generalized over all sectors. The systematic classification of product categories based on polymer characterization and industrial sector done in this paper can provide a guidance for authorities to facilitate efficient planning for plastic waste reuse and recycling.